M1.8 M1.2 Dental Implants Orthodontic Titanium Micro Screw

M1.8 M1.2 Dental Implants Orthodontic Titanium Micro Screw(M5,M6,M10) We are a professional manufacturer of machine scre

Description

Basic Info.

| Model NO. | M5-M10 |

| Grade | Stainless Steel |

| Class/Grade | 4.8, 8.8, 10.9 |

| Surface Finishing | HDG, Black, Color-Zinc, Blue-White Zinc |

| Used | Machine Screw-Machinery, Building |

| Head Type | Hex Head |

| International Standard | DIN, ANSI, GB, JIS, Bsw, GOST |

| Available Material | Carbon Steel, Stainless Steel |

| Transport Package | 20-25kg/Carton+900kg Pallet |

| Specification | M5-M10 |

| Trademark | HN |

| Origin | China |

| HS Code | 7318159090 |

| Production Capacity | 500ton/Month |

Product Description

M1.8 M1.2 Dental Implants Orthodontic Titanium Micro Screw(M5,M6,M10)We are a professional manufacturer of machine screws. We have capabilities to manufacture machine screws in length

of 1/4" to 8" and diameters of up to M2 to M6.3. Materials of low carbon steel from C1022.

We are able to achieve and fulfill customers' demands. If you have interests in our machine screws or more questions,

please don't hesitate to contact us.

ASME standards specify a variety of "Machine Screws" in diameters ranging up to 0.75 in (19.05 mm). These fasteners

are often used with nuts as well as driven into tapped holes. They might be considered a screw or a bolt based on the

Machinery's Handbook distinction. In practice, they tend to be mostly available in smaller sizes and the smaller sizes are

referred to as screws or less ambiguously as machine screws, although some kinds of machine screw can be referred to

as stove bolts.

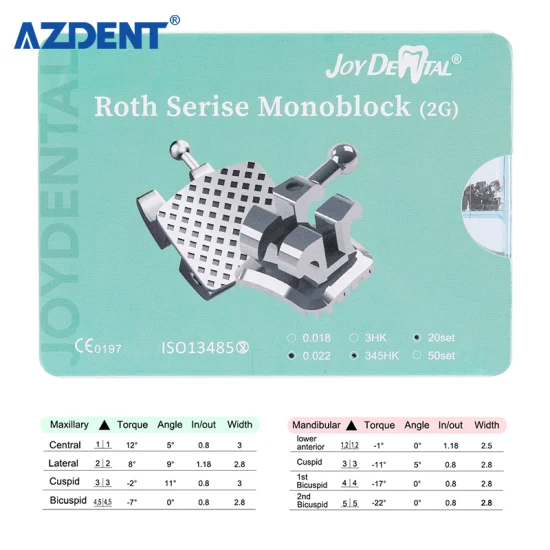

| Products name | Dental Implants Orthodontic Titanium Micro Screw | ||||||

| Standard: | DIN,ASTM/ANSI JIS EN ISO,AS,GB | ||||||

| Material | Stainless Steel: SS201, SS303, SS304, SS316,SS316L,SS904L,F593 | ||||||

| Steel Grade: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; ASTM: 307A,307B,A325,A394,A490,A449, | |||||||

| Finishing | Zinc(Yellow,White,Blue,Black),Hop Dip Galvanized(HDG),Black Oxide, Geomet,Dacroment,anodization,Nickel plated,Zinc-Nickel plated | ||||||

| Production Process | M2-M24:Cold Froging,M24-M100 Hot Forging, Machining and CNC for Customized fastener | ||||||

| Customized Products Lead time | Busy season:15-30days,Slack seaon:10-15days | ||||||

| Stock Products | Steel:4.8Grade DIN6923,8.8Grade 10.9Grade of GB5783 and GB5782 Stainless steel: All DIN Standard stainless steel Bolt | ||||||

| Free Samples for standard fastener | |||||||

| For more information visit:hainafastener.en.made-in-china.com | |||||||

Dental Implants Orthodontic Titanium Micro Screw

Service

Professional Manufacturer: All of our Fastener are designed and manufactured according to buyers' specification and performance.

Quality is guaranteed: Durability testing and critical technical design to enhance fasteners lifetime.

Cost effective: Competitive prices with factory directly supply

Perfect fastening solution with 20 years experiences to solve your problem: Wide range of parts selection.

Customized Ideal Fasteners: customized services according to the samples and drawings offered.

If you are not sure about what exactly you need - feel free to contact us anytime and get professional assistance from us.

Prev: Orthodontic Micro Implant / Micro Screw / Titanium Dental Implant Screw

Next: Screw Driver Orthodontic Micro Implant Slim Implant Driver

Our Contact

Send now