Sps Spark Plasma Sintering System (20t, 1600C) for Material Annealing and Hot Pressing Bonding

SPS spark plasma sintering System (20t, 1600C) for material annealing and hot pressing bonding Description of Spark Plas

Description

Basic Info.

| Model NO. | CY-SPS-20T |

| Pressure Control System | PLC |

| Sintering Stroke | 100 mm |

| Input Voltage | AC220V 50/60 Hz Three Phases |

| Output Current | DC 0 - 1500 a (Digital Controlled) |

| Power | 20 kVA |

| Transport Package | Wooden Case |

| Specification | Spark Plasma Sintering System |

| Trademark | CYKY |

| Origin | China |

| HS Code | 85141090 |

| Production Capacity | 100 Sets Per Month |

Product Description

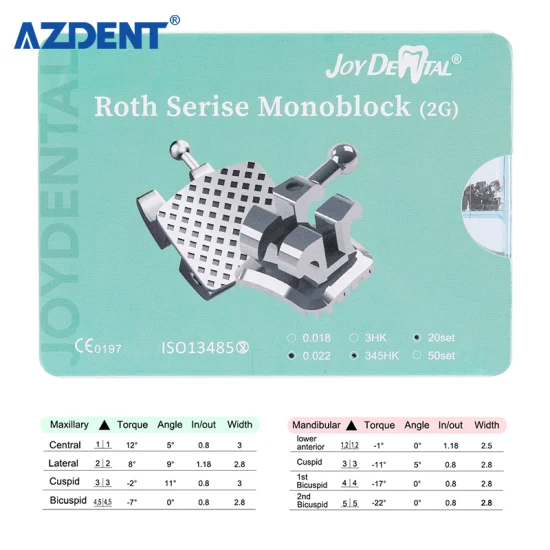

SPS spark plasma sintering System (20t, 1600C) for material annealing and hot pressing bondingDescription of Spark Plasma Sintering System:CY-SPS-20T is a Spark Plasma Sintering System is designed for a wide range of material research up to 1600ºC. It can be used for sintering, sinter-bonding, surface treatment, and synthesis. The sample material can be metals, ceramics, nanostructured material, and amorphous material. This system is perfectly fit solid electrolyte and electric thermal material research.Specification of Spark Plasma Sintering System:

| Configuration | ·Stainless Steel Chamber - Suitable for Controlled Inert Gas or Vacuum Condition·Sintering Press Unit·Sintering DC Pulse Generator·Vacuum Unit·Sintering Control Unit |

| Power | 20 KVA |

| Input Voltage | AC220V 50/60 Hz Three Phases |

| Output Current | DC 0 - 1500 A (Digital Controlled) |

| Output Voltage | DC 0 - 10 V (Digital Control) |

| Pulse Frequency | ·5 - 255 ms Adjustable·2 - 1000 Hz adjustable |

| Maximum Temperature | · 1200ºC with K-type thermal couple · 1600ºC with B-type thermal couple ·Two types of thermal couple are included |

| Temperature controller | ·Precision Eurotherm temperature controller is built in·Overshoting temperature is less than 5ºC at the feast heating rate·Temperature accuracy : < 0.1ºC |

| Hydraulic Presss | ·Manual operated hydraulic press to apply pressure.·Max pressure: 20 T·Digital Pressure guage is built in with over-pressure alarm. |

| Sintering Die Set Dimension | ·OD. 85- 100 mm diameter made of HIP graphite in Japan·ID: 20 mm - 50 mm ·Sintered Sample size : 20 - 50 mm depended on sintering temperature.·Made of high purity graphite by HIP processing, Max. Pressure for the die is 50 MPa, and Max. Load from the hydraulic press is dependent on die 's IDo 0.5"ID Max. 0.5To 1.0 ID: Max. 3T |

| Sintering Stroke | 100 mm |

| Vacuum Chamber | ·Vertical vacuum Chamber·Inner Double Layers Stainless Steel Reflectors·Rotary Pump included |

| Max Vacuum Level (Room Temperature) | · 10 Pa (7.5 x 10^-2 torr) with the mechanical pump·One double stage mechanical pump is included·1 Pa ( 10x10-4 torr ) with optional turbo pump ( click picture below right to order ) |

| Pressure Control System | PLC |

| Pressure Stability | ≤±0.1MPa |

| Pressure Rising Rate | ≤2Pa/hr |

| Max Heating Rate | 300ºC/min |

| Safety Devices | Emergency Stop System and Warning Alarm System |

| Water Cooling | 58L/minute recirculating water chiller is included fro cooling pushing head |

| Standard Accessories | ·SPS Sintering Graphite Die Set·Graphite Spacer·K & B typeThermal Couples·O-rings·Clamping Tool |

| Dimension | ·Power Supply :760 L X 460 W X 1820 H, mm ·Furnace: 970 L X 720 W X 1400 H, mm |

| Compliance | ·CE certified·NRTL certification is available upon request at the extra cost |

| Warranty: | ·One year limited warranty |

Reference pictures of Spark Plasma Sintering System:

Founded in 2005, Zhengzhou CY Scientific Instrument Co., Ltd. is a company specializing in the development and production of laboratory technology research equipment. The products are mixed, pressed, burned, cut, ground, polished, coated, analytical equipment and related consumables. Products include laboratory sintering equipment, coating equipment and so on. At present, it has been exported to 25 countries and regions such as the United States, Europe, and Southeast Asia, and has been well received by various scientific research units.

We have a mature technology research and development team, the number of technicians is 33, the company has 150 people, more than 500 square meters of office space, the factory covers an area of about 1,500 square meters located in Zhengzhou High-tech Zone Electronic Industrial Park. The products are mainly located in the research market, serving scientific research in the labs of universities and colleges, and can also customize products according to your needs.

Q. Are you a manufacturer or a trading company?

A. We are professional laboratory instrument manufacturers, have their own design team and factory, have mature technical experience, and can guarantee the quality of products and the optimal price.

Q. How is your company's product after-sales service system?

A. The product warranty period is 12 months, we can provide lifetime maintenance. We have professional pre-sales and after-sales departments that can respond to you within 24 hours to resolve any technical issues.

Q. How long is your delivery time? If I want to customize the instrument, how long does it take?

A.1. If the goods are in stock, it is 5-10 days. 2. We can provide customized services for our customers. It usually takes 30-60 days depending on the specifications of the custom instrument.

Q. Our country's power supply and plug are different. How do you solve it?

A. We can supply a transformer and plug according to your local requirements according to the power plug of different countries.

Q. How to pay?

A.T / T, L / C, D / P, etc., it is recommended to use Alibaba Trade Guarantee.

Q. How is the package of goods? Delivery methods?

A.1. Standard export fumigation sign wooden box packaging 2. Express, air, sea shipping according to customer requirements, find the most suitable way.

More questions, please contact customer service

Prev: Good Quality Dental Orthodontic Buccal Tube 4PC/Bag

Next: Azdent Orthodontic Single Bondable Dental Monoblock Buccal Tube 200PCS

Our Contact

Send now